John L. Grove is the inventor of the first aerial work platform. Wanting to perform high-altitude work quickly and without scaffolding, he invented the first aerial work platform in the United States in 1970. It was an instant success! The first prototype vehicle with a self-propelled carriage and a lifting arm with a basket proved to be much more efficient than traditional methods. It revolutionized the world of high-altitude work. To this day, aerial work platforms continue to evolve, differing in form, reachable height, and load capacity. Adding revolutionary services like short- and long-term rental, you get a machine that is indispensable for both private individuals and companies.

In this simple and comprehensive guide, we will explore together the different types of aerial work platforms, their functions, and their use.

The Importance of Aerial Work Platforms in Work

When we talk about revolutionizing the world of high-altitude work, we refer to the speed and simplicity with which operations are now carried out. An aerial work platform is easy to manoeuvre and has much smaller dimensions than traditional fixed scaffolding. On one hand, the latter is preferred for jobs that last several months, as they remain fixed and do not require fuel. On the other hand, they require special permits and more labour to move the necessary materials.

Aerial work platforms facilitate and accelerate activities of construction companies with their design, robust structure, and ability to extend over many meters in height. But not only that! They also benefit companies involved in installation, maintenance, or cleaning. Thanks to services like machine rental, private individuals can also benefit from them, whether for hobbies or DIY projects around the house.

The Main Types of Aerial Work Platforms

Are you sure you need a lifting machine, but are having trouble finding the best one among so many types and models? We are here to help you differentiate them! Although the use for all available models is almost identical, they mainly differ in form, functionality, and maximum load capacity. Here are the most well-known aerial work platforms:

Vertical Aerial Work Platforms

Vertical aerial work platforms are the most efficient and frequently used model. Known for their simple construction, they consist of a self-propelled carriage and a lifting system with crossed arms. A basket with onboard controls is attached to these. The basket can have different dimensions, allowing you to lift the necessary materials for the job.

They are compact and easy to manoeuvre, so they are often used in tight spaces, factories, or halls. The best-suited applications include activities like building restoration, painting, installation of systems, or laying drywall.

Another notable distinction concerns the built-in motor of the aerial work platforms, whether thermal or electric. While the operation of the first is intuitive, more and more entrepreneurs prefer electric aerial work platforms.

Electric Vertical Platforms

These are generally more compact and suitable for tighter spaces or less maneuvering room. The battery housed in a closed steel container makes the machine lighter. If the idea of making your activity more environmentally friendly isn’t enough to convince you, here are the other benefits of electric vertical aerial work platforms:

- They are much quieter than others, allowing compliance with noise protection regulations in residential areas or historic centres.

- No power connection is required.

- There is no risk of damaging the cable connection or tripping over the cable.

- The built-in batteries have good autonomy, usually sufficient for the entire workday.

But that’s not all! Electric vertical platforms reach heights of up to 20 meters, and their overall dimensions do not exceed 240 cm in width. Although they have a higher purchase price than others, you can achieve the best quality-to-price ratio through a good rental service!

Vertical Platforms with Combustion Engine

It cannot be denied that these types of aerial work platforms also have their advantages, especially the lower price. Again, rental seems to be the best alternative, as it eliminates expenses for maintenance or repairs. Most of these aerial work platforms are equipped with stabilizers, making them very suitable for outdoor work and on inclined or firm ground. They are frequently used for all types of construction work, industrial assemblies, and even tree care. The need to ensure stability as much as possible leads to these vertical platforms having thick, resistant tires. And in some cases, they are mounted on a tracked chassis, which improves ground contact. With this model, you can reach heights exceeding 20 meters. However, note that the design is certainly bulkier and can reach up to 400 cm in width.

Aerial Work Platforms with Arm

These aerial work platforms are also known as telescopic or articulating boom lifts. They consist of a movable carriage that uses a lifting system with an arm to move a basket upwards. This basket is large enough to lift both workers and materials. And it features easily accessible controls for the operator on board.

Telescopic Boom Lifts

Aerial work platforms with a telescopic mechanism can perform wide horizontal movements. While articulated platforms offer greater flexibility and can overcome obstacles. Both models typically feature a hydraulic rotation system, also known as a Jib, which allows rotational movements of over 360 degrees. Their use is very versatile and suitable for indoor and outdoor areas. However, you must pay special attention to the ground you are working on, as they do not have stabilizers.

In fact, the centre of gravity of this structure is very low, and stabilization is ensured by the weight of the frame. The lower part of the carriage is equipped with two axles and wheels, providing the greatest freedom of movement. Thanks to the dimensions of the platform and its flexibility, these self-propelled aerial work platforms with an arm are suitable for any type of work. Whether it’s repair, construction, maintenance, inspection, or installation.

Truck-Mounted Aerial Work Platforms

To enjoy the greatest mobility and versatility, this is certainly the type of aerial work platform you should choose. It is the typical lifting equipment that is not mounted on a fixed structure or with wheels. But on the back of a truck. The greatest advantage is the ability to drive freely on the road and quickly move to the workplace or construction site.

You will no longer need heavy vehicles to transport your aerial work platform. And you can still use it for the same applications as those already presented. In this case, stabilization is ensured by the weight of the two frames: that of the truck and the auxiliary frame attached to the first with screws. Although they are also equipped with stabilizers, it is not recommended to use these machines on very difficult or inclined terrain.

Driver’s License for Truck-Mounted Platforms

Due to their great mobility, these tools are frequently used for renovations, maintenance, or installations. To differentiate between the various models, reference is often made to the required driver’s license, namely:

- Driver’s license B for all vehicles with a total weight of 3.5 tons.

- Driver’s license C for all vehicles with a total weight between 3.5 and 6 tons or over 6 tons.

More and more companies and entrepreneurs prefer truck-mounted aerial work platforms that require a driver’s license B. Many models can reach heights of up to 28 meters, which is sufficient for any type of work. But that’s not all! Given their simple handling, these aerial work platforms are often used for lifting heavy loads of materials or people. And they often feature a hook or pulley for more versatile use.

Can I Drive an Aerial Work Platform on the Road?

In the second case, it is good to know that driving on the road is allowed. However, only for vehicles with a total weight of less than 6 tons and can reach heights of up to 30 meters. Aerial work platforms with a weight over 6 tons are defined as heavy machinery. And are used to perform complex interventions that cannot be resolved by other types of equipment. The maximum reachable height exceeds 60 meters, with the possibility of performing wide horizontal movements. Given the special structure of these vehicles, a special permit for heavy vehicles is required for driving on the road. Both truck-mounted aerial work platforms requiring a driver’s license B and those requiring a driver’s license C must be registered with INAIL in the category of auto cranes. And undergo a double annual inspection, as prescribed by law.

Types of Truck-Mounted Aerial Work Platforms

In addition to the distinction already discussed, there are three other aspects to consider when choosing a truck-mounted platform, namely whether they are:

- Articulating boom lifts: the best for achieving great working heights, as they have flexible articulated or telescopic arms. The structure features a pivot axis with a hydraulic-mechanical support system that holds the extendable articulated connection.

- Telescopic boom lifts on trucks: the built-in arm performs quick lifting operations up to a maximum of 40 meters. Safety and stability are ensured by hydraulic stabilizers, while the 180-degree rotating base is ideal for reaching even tighter areas.

- Platforms with or without a Jib: the latter plays a crucial role in the flexibility of the platform. Platforms equipped with a Jib can increase the number of movements by moving the operator both vertically and horizontally. The Jib can even be removed, as it is attached to the crane assembly with four plugs and a bolt.

Tracked Aerial Work Platforms

Tracked aerial work platforms, also known as “spider lifts,” were specifically developed to offer more stability and safety on uneven or inclined terrain. The name “spider” comes from the special structure and stabilizers that resemble the legs of a spider. The two most used models fall into two categories: with articulated arm or with telescopic arm and Jib. Both are lightweight and capable of reaching the required heights even in tight spaces.

In fact, they are frequently used on construction sites when the work area makes it very difficult to access with other wheeled vehicles. Another distinction should be based on the project’s requirements: if you need a very compact tool, you must opt for the articulating ones. However, if you need to reach greater distances and more flexibility, the solution is certainly the platform with a telescopic arm.

What Are Articulating Platforms?

These aerial work platforms feature a movable tracked vehicle frame that carries the basket with onboard controls. The lifting system with telescopic or articulating arm allows for lifting operations and horizontal movements. As well as complete rotations of 360 degrees. Unlike other aerial work platforms, these do not have wheels and must therefore be transported with another vehicle.

Versatile, reliable, and efficient, these aerial work platforms are ideal for tight access. If there are soles or other obstacles that prevent access to other aerial work platforms. They can be used to lift materials or the operator, are equipped with a hook or pulley. And must be registered with INAIL to undergo annual inspections.

The built-in motor can be of two types:

- Thermal: often also referred to as a combustion engine, it requires fuel (diesel or gasoline) to operate.

- Combined: i.e., electric and thermal, it uses the combined effect of both to achieve maximum performance and durability. These motor types typically use electric power for starting and remain operational thanks to combustion.

Tracked aerial work platforms are also preferred due to their low weight and dimensions. As well as their ability to reach heights of over 50 meters. Additionally, the rental price for these platforms is certainly cheaper compared to other types of equipment. However, a suitable driver’s license is also required for operation.

Descending in Height: How Does It Work?

When we talk about “descending in height”, we refer to the terminology used by aerial work platform operators to define access to elevated areas with an aerial work platform. This includes ascending and descending from it. It is a highly risky activity also considered in the EN 280 standard and prohibited if appropriate measures have not been taken.

What Are Mobile Lifts?

First, it’s essential to know that not all platforms are designed to facilitate the operator’s descent. The EN 280 standard, introduced in 2015, sets clear obligations for manufacturers regarding information and construction. Ascending or descending can only occur from the frame and when the vehicle is stationary. Therefore, the manufacturer must clearly indicate which access points are available.

The user manual becomes indispensable and means a ban for the operator to use access points not marked as safe or suitable. Only machines with clear indications of entry and exit points can be defined as mobile lifts. Additionally, a good definition of procedures by the manufacturer is required

Risks Associated with Descending in Height

Descending in height requires a highly risky activity that not only endangers the operator but also the entire team and can damage the aerial work platform. The risks mentioned in the standard include:

- Incorrect Operation: In this case, correct preparation of the user and understanding of the rented or purchased equipment are crucial. Collisions, damage, or jerky movements could occur. Therefore, it is important to read the manufacturer’s user manual.

- Sudden Movements During Lifting or Ascending: Both movements cause unavoidable vibrations of the structure. An incorrect ascent or descent method poses the risk of damage or loss of balance by the worker.

- Risk of Falling from Height: This poses a danger not only to the user but also to the entire team, as the machine could tip over due to the push generated by the fall.

How to Address These Risks

The best methods to address these risks are the use of a correct procedure for the operator’s ascent and descent without neglecting the correct use of a work platform suitable for descending in height. To comply with the safety requirements of EN 280 and Directive 2006/42/EC, it must offer:

- Increased Stability and Durabilityof the machine by reducing the working configuration and the maximum capacity of the work platform.

- Possibility of Using Safety Harnessesfor the operator.

- Correct Maintenanceof fixed parts.

- Structure Designed for Load Changesduring ascent or descent.

How Does Descending in Height Work?

Considering the mentioned risks, to ensure you have chosen the best work platform, you must consider the position of the construction site, the type of work, and the type of work platform needed. It goes without saying that proper training of operators is fundamental!

Additionally, work platforms with a rear connection of the extendable structure and an inward-opening door are preferred for descending in height.

Access Methods to Elevated Areas

There are several access methods to elevated areas with different methods for leaving the work platform:

- Access to a Closed Area with Railings: In this case, the basket reaches the inner area of the protected area thanks to the extendable arm. This is the safest and most effective method for descending in height.

- Access to a Protected Area Through an Entrance: The work platform approaches the entry point, which is not protected by railings and requires a securing point. The risk is that the operator may lose balance during the descent phase.

- Access to an Unprotected Area with an Accessible Securing Point: The worker can secure themselves before leaving the work platform.

- Access Without Securing Points: This is the riskiest method. The operator must create a mobile securing point, which may not be sufficiently secure.

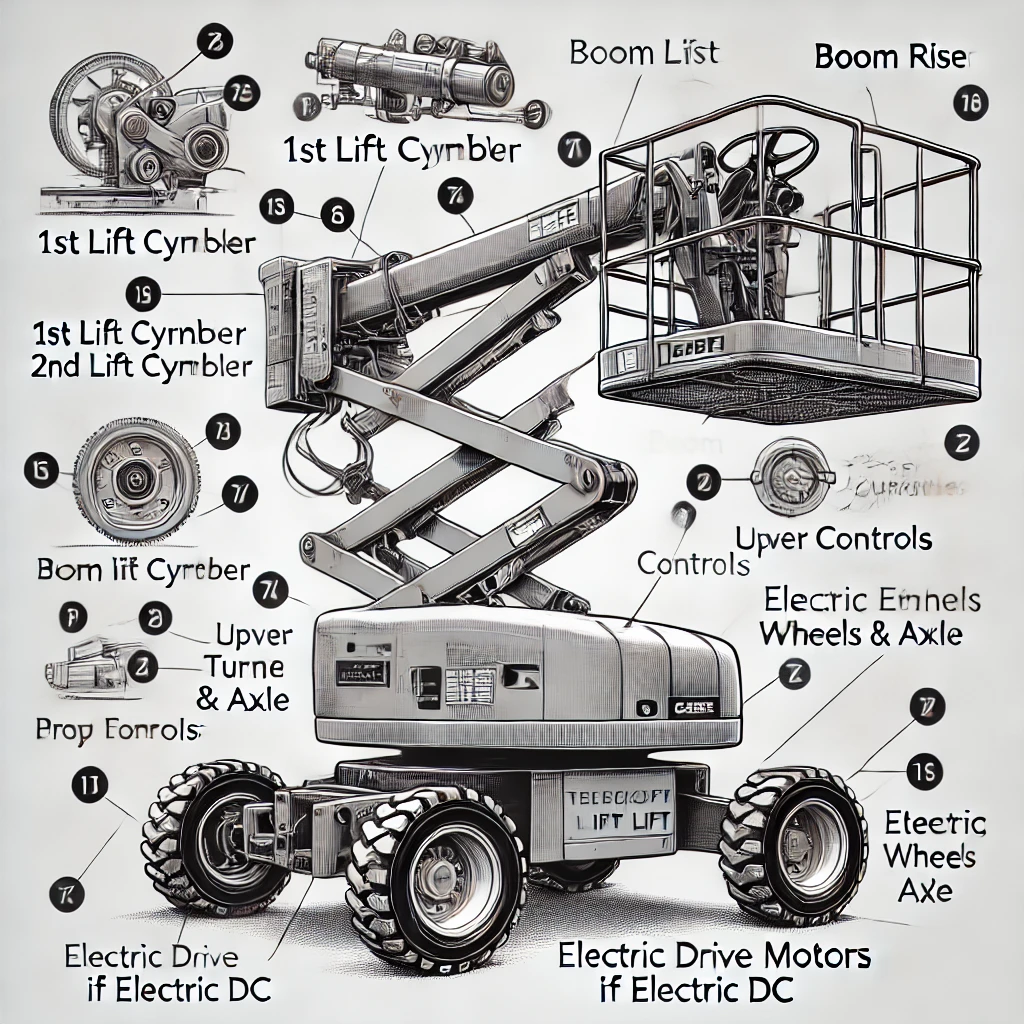

Main Components of a Work Platform

Work platforms differ in reachable height, maximum weight, and mobility but have certain indispensable structural features:

The Frame

Often referred to as the base module or chassis, it is the basis of the entire work platform. It holds the extendable part stable and can be self-propelled or simply towable. The frame can have different features depending on the type of work platform.

Stabilizers

These are additional components mounted on the chassis. They ensure the work platform remains stable and firm during operation. They are mainly used in truck-mounted cranes or crawler work platforms and distribute the load better by increasing the contact area.

Extendable Structure

Often referred to as the arm of the work platform, it allows the platform to reach the required height. It is attached to the chassis with screws and can be executed as a telescopic arm, articulated arm, or with a scissor mechanism.

Hydraulic System

Consists of valves, manometers, and flexible or rigid pipes, specifically designed to support high pressure during operation. To ensure maximum safety, work platforms are equipped with indicators for maximum pressure values and blocking valves to prevent jerky movements that could damage the machine.

The Man Basket

Also known as just the “basket,” it is the movable part connected to the extendable structure and reaches working areas. The operator can secure themselves inside and perform repair, construction, or inspection work. It is made from lightweight and resistant materials and is usually equipped with a rotating mechanism and an entrance door. The surface must be non-slip and drainable to avoid possible work accidents.

Electrical Control

To operate any work platform, an electrical control panel is needed, typically installed on the ground and equipped with protective switches. Many models have controls on the work platform as well as connections to use electrical tools. The entire system is protected against possible electrical or mechanical damage and can only be operated by authorized personnel with access codes.

Important Factors for Choosing Aerial Work Platforms

If you need a work platform but don’t know which model is best for you, no problem! If you consider the main factors selected by experts, you will understand which models are the best and which work platform is best suited for your project. Here are the most important factors:

Maximum Reachable Height

To choose the best work platform for you, you should assess the maximum height you need to reach. This helps you avoid leaning too far or making jerky movements that can cause vibrations or loss of balance. Telescopic or articulating boom lifts reach up to 40 meters, while truck-mounted work platforms reach up to 70 meters. Tracked work platforms reach about 30 meters, and those with spider configurations usually do not exceed 35 meters.

Maximum Load Capacity

Most work with aerial work platforms requires lifting operators and heavy materials. To avoid damage or work interruptions due to possible replacement needs, it is better to opt for a more resistant work platform with greater strength.

Accessibility to the Construction Site and Ground Type

Many of the aerial work platforms studied are characterized by stability and the ability to reach high or difficult areas. For indoor work, vertical or self-propelled models are best suited. If the construction site is sloped and has many physical obstacles, a truck-mounted work platform or a tracked work platform is better, as they offer more stability.

Size of the Work Area

The maneuvering space is also important! If you are renovating in tight spaces, you need to rely on vertical aerial work platforms or those with articulating or telescopic arms.

Type of Built-in Motor

In our guide, you have seen that there are aerial work platforms with thermal, electric, or combined motors. Electric platforms are the quietest and most environmentally friendly and can be operated for a whole working day. Those with thermal motors are powered by gasoline or diesel, require more maintenance, but are also more powerful and economical. The combined motor uses both thermal and electric power but is also the most expensive due to its specialty.

Processing and Transportation Costs

To save on transportation costs, self-propelled aerial work platforms that can be towed or truck-mounted work platforms that can be driven with a Class B or C driver’s license are the best options. For complex work, the tracked work platform is the only alternative, which does not have wheels and therefore must be transported with another vehicle. Also, consider the processing costs for storage and maintenance or the costs of fuel.

Accessories and Compatibility with Descending in Height

To safely perform descending in height, you must ensure your aerial work platform is equipped with an inward-opening door and the necessary accessories for securing the operator. Equally important are dual controls and safety blocks, both on the ground and on the work platform, as well as the presence of power outlets to use tools.

Total Price

It is impossible for the final price of a aerial work platform not to influence your decision. Therefore, we recommend opting for rental, which is the most economical, versatile, and adaptable option. If you want to own the machine, you can save by purchasing at auctions or used products.

How to Choose the Best Work Platform

Now that you know which factors are important for selecting a work platform, let’s look at the different types and their uses. This way, you’ll know how to choose the best work platform for your job.

To perform operations at heights with maximum safety, the following platforms are designed for specific activities:

Vertical Aerial Work Platforms

These models are the simplest, most resistant, and easiest to operate. However, they are the least mobile and cannot reach over obstacles. Given their maximum lifting height and lack of stabilizers, these models are best suited for tight spaces, such as factories or simple construction work.

Articulating or Telescopic Boom Lifts

This machine is the most flexible and can reach great heights, even over obstacles. The platform can rotate 360 degrees (if equipped with a jib). Although it cannot lift large loads, it facilitates the operator’s movements and allows for safe exit at heights. These models are particularly suitable for tight spaces, both indoors and outdoors, for construction, maintenance, or installation work.

Truck-Mounted or Self-Propelled Platforms

If you know you need to move frequently, such as performing multiple jobs simultaneously, one of these work platforms is the best choice. Whether you can drive or tow it, you will enjoy maximum mobility and versatility. These platforms are not ideal for DIY enthusiasts, as they require special permits. However, they remain the best option for complex tasks like industrial renovations or construction projects.

Tracked Spider Lifts

This aerial work platform is the best choice for complex work on uneven or sloping terrain. Thanks to its stabilizing arms, it offers maximum stability but is difficult to move or transport. This model is particularly suitable for construction companies with a sufficient budget to cover all necessary operating costs.

If you’re still unsure which work platform is best for you, renting could be a good solution. This service allows you to try different types of work platforms for a daily fee. A good rental service will help you select the most suitable models for your project and allow you to add accessories, adjust costs, and exchange the machine if it proves insufficient.

Renting Work Platforms: Things to Consider

You can’t wait to rent a work platform, but you want to ensure you’re choosing the best service? We can help! Whether you’re an experienced professional or a beginner, the key points to check are the same. Read through the following tips and avoid common mistakes renters make:

Ensure It’s the Right Type of Aerial Work Platforms

A good rental service offers a wide range of machines and equipment. You choose the product that best fits your project. To avoid mistakes, consider basic elements like the type of ground you’ll be working on and the maximum weight you need to transport. Don’t forget the height you need to reach, additional costs, and the desired drive type. If you’re unsure or need help, you can always contact customer service and request support from an expert. Don’t worry if you make a mistake—you can always exchange the work platform.

Check the Maximum Payload

As you’ve noticed, there are different types of work platforms for specific jobs. The maximum payload is closely related to the shape of the work platform. For example, articulated platforms are preferred for exiting at heights, while self-propelled vertical platforms can lift large loads. Equally important are stability and the ground on which the machine must stand while lifting the load.

Ensure It’s Suitable for Descending at Heights

It’s important to know that not all work platforms are suitable for this type of operation. Given the high risk, there are specific legal requirements for the construction of the device that ensure both the operator, and the machine are safe. Before proceeding with renting work platforms, ensure the manufacturer has complied with the prescribed rules.

Choose the Right Drive

Work platforms can be equipped with thermal, electric, or combined engines. Here, too, the choice must be carefully weighed and compared with the duration of the project and its location. If a thermal model proves cost-effective in the long run, an electric model is preferable for quiet work. Some communities have strict rules to protect public peace, and sometimes customers prefer a more environmentally friendly option.

Don’t Forget Operating and Transport Costs

Certain types of work platforms, such as crawler work platforms, must be transported with another vehicle. But that’s not all—some renters leave it to the customer to perform small maintenance tasks like cleaning and storage during work. To make a correct choice, pay attention to every additional cost factor and ensure it’s included in your budget.

Add Insurance

Good coverage for minor damage protects you from potential damage and malfunctions that can occur due to the nature of the work. Ultimately, it may be worth paying a small percentage more to save time and money.

Ensure Your Operator Has the Required Qualification

To operate and use platforms, a license or qualification is legally required. You can always choose between renting with or without an operator, but to delve deeper, read on!

Renting Aerial Work Platforms Without an Operator: Pros and Cons

Known as “cold rental,” renting without an operator means you simply lease the equipment without an experienced operator. To comply with legal regulations like D. Lgs. n. 81/2008, it’s important that the company already has an experienced operator who can safely operate the work platform. Here are the pros and cons:

Pros:

- You save money, as the final price only covers the rental of the work platform, without the operator’s working hours.

- The work is performed by an experienced member of your team whom you already know.

- You don’t risk not being able to rent the equipment because the operator is unavailable.

Cons:

- For complex operations, you might need the expert from the renter.

- Small companies or DIY enthusiasts usually don’t have the required qualification to operate work platforms.

- Your operator might take too much time to understand the controls and features of the rented work platform, even if they are prepared.

Renting Work Platforms With an Operator: Pros and Cons

Renting work platforms with an operator, or “hot rental,” is a service that also provides an experienced operator. Here are the pros and cons:

Pros:

- The operator knows the work platform and can perform complex operations in the shortest time.

- You don’t need to hire a new employee or attend necessary training to obtain certification.

- For some projects with difficult and complex operations, hot rental is the only solution.

Cons:

- The costs for hot rental are higher than for cold rental.

- You must submit the rental request in advance to ensure an experienced operator is available.

Frequently Asked Questions About Aerial Work Platforms

In this section, we’ve summarized some of the most frequently asked questions about work platforms to help you with your selection.

What is a Work Platform?

A work platform is a lifting device specifically designed to facilitate work.

Especially in construction, maintenance, installation of facilities, or gardening. It offers the ability to lift operators or large quantities of material due to its power, stability, and ability to reach great heights.

What Are Work Platforms Used For?

Work platforms are used in various fields, from construction to gardening and industrial cleaning.

Large and small companies use them for high-rise work, renovations, or simply to overcome certain obstacles. They can be used by electricians to install lights or antennas or by gardeners to prune large trees. Thanks to their features and diverse functions, work platforms are among the most versatile machines.

Can Work Platforms Be Operated Without a License?

No, work platforms cannot be operated without proper training.

Due to the high risk involved in working at heights, D.lgs 81/2008 and the State-Regions Agreement of 2012 stipulate that all operators wishing to use platforms must have the required certification. This involves attending courses for work platforms and passing the final exam. The certification has a limited validity period, usually five years, and must be renewed regularly.

In Which Areas Are Work Platforms Most Frequently Used?

Work platforms are among the most versatile machines.

There are work platforms for pruning trees, moving, and construction. The main models differ in terms of power, reachable height, and stability level. There are platforms for indoor work, such as factories or warehouses. And others that are more robust and weather-resistant, suitable for construction sites or renovations.

What Is the Difference Between Work Platforms With and Without Stabilizers?

The main difference between these types of work platforms lies in the achievable stability level.

Models with stabilizers, such as spider lifts with two or more side legs, remain stable even on difficult or sloping terrain. Work platforms without stabilizers rely on the balance between the frame and boom to stay firmly on the ground. However, they cannot be used on uneven terrain.

What Heights Can Work Platforms Reach?

The maximum reachable height varies depending on the type of work platform.

Truck-mounted work platforms range from a minimum of 14 meters to a maximum of 68 meters, self-propelled from 4 to 40 meters, while crawler work platforms typically reach heights between 10 and 32 meters. Given the continuous technological development, we do not exclude the possibility that there are models that exceed these ranges and enable work at heights with maximum safety.

Our Conclusions

Work platforms are certainly among the most frequently used machines in various fields and facilitate the completion of a project when used correctly. It’s important to note that safety comes first. Therefore, these devices must only be operated by certified and competent operators.

rentmas offers you the guarantee of perfect machines and the advantage of flexible rental tailored to your needs. On our website, you’ll find machines and equipment of all kinds for your work, as well as a wide selection of work platforms. Discover them now and contact us for more information. Finally, remember: “Whoever climbs higher sees further.”