In the bustling world of warehouses and distribution centers, forklifts and reach trucks stand as indispensable workhorses of industry. At the heart of these powerful machines lies a component that often goes unnoticed yet plays a crucial role in their functionality: the forklift mast. Forklift masts extend smoothly upward, enabling operators to precisely maneuver loads with remarkable stability and control.

The mast system, essentially a lift truck’s vertical assembly, ranges from simple single-stage forklift mast designs to sophisticated forklift quad-mast configurations. Modern mast designs strike a delicate balance between maximum lift height, load capacity, and visibility – three factors that can make or break efficiency.

Forklift masts transform simple hydraulic power into the reliable lifting force that keeps global supply chains moving. This article explores the different types of mast configurations and their unique advantages, helping you choose the right forklift mast technology for your project.

A basic introduction to reach truck and forklift masts

Masts play a crucial role in the operation of forklifts, reach trucks, pallet stackers, and numerous other types of machinery designed for material handling. Essentially, the mast is the component of your machine responsible for raising and lowering loads, ensuring efficient and safe movement of materials within various environments such as warehouses, construction sites, and manufacturing plants.

Beyond the basic functionality of lifting and lowering, many masts are equipped with advanced features that enhance their versatility and performance. One such feature is the tilt function, which allows operators to adjust the angle of the forks. This adjustment is particularly important for preventing loads from slipping off, thereby enhancing the safety and stability of the lifting process. Another key feature is the side-shift capability, which facilitates the horizontal, sideways movement of the forks. This function is invaluable for precise placement and retrieval of loads, allowing operators to maneuver in tight spaces and align loads more accurately.

These additional functionalities of the mast, including tilt and side-shift, are typically powered by the machine’s hydraulic circuit. The hydraulic system provides the necessary force and control to perform these movements smoothly and efficiently. By utilizing hydraulics, these machines can handle heavy loads with ease, ensuring that operations are not only efficient but also safe for the operators and surrounding environment.

Your forklift mast height dictionary

Free lift cylinder

The lift cylinder rod and assembly that lift the carriage prior to the engagement of any of the forklift’s rear cylinders

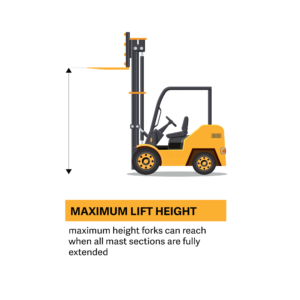

Maximum lift height

The maximum height a machine’s forks will reach when all mast sections are fully extended

Extended height

Indicates the height of the top of the mast when it is fully extended

Lowered height

Indicates the height of the top of the mast when it is fully collapsed

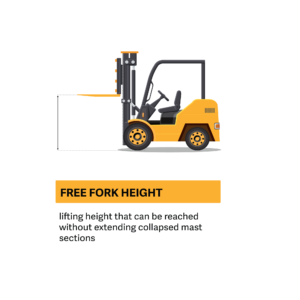

Free fork height

The height that can be reached in lifting a load without extending collapsed mast sections

Understanding free lift: A key forklift and reach truck specification

Before we get into the different types of forklift masts, it is important to understand what free lift is.

Ever wondered how high your forklift’s forks can go before the whole mast starts extending upward? That’s what we call “free lift” in the material handling world – it’s defined as the maximum height you can raise your forks without changing the mast height. You’ll notice this happening in two main scenarios: either when those inner forklift mast rails slide up higher than the outer ones, or when the carriage or load backrest rises above the outer rails. This seemingly small detail can make a huge difference in your warehouse operations, especially when working in spaces with height restrictions.

The five main types of forklift masts

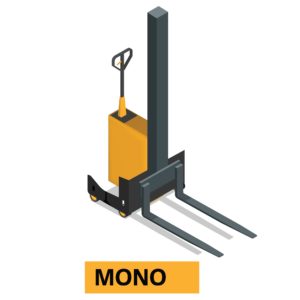

MONO

Mono masts are characterized by their simple, single-column design. This central structure houses the lifting mechanism, which elevates the load carriage vertically. Unlike multi-stage masts, the mono mast’s overall height remains relatively constant throughout the lifting process. This design is particularly suited for applications with limited overhead clearance, such as loading and unloading trucks or working in confined spaces.

- Sections: 1

- Free lift: no

- Ability to extend: no

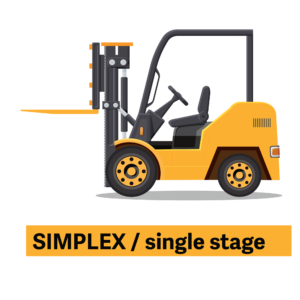

SIMPLEX / Single stage

The simplex mast, also known as a single-stage forklift mast, is a simpler design that consists of a single channel that extends upwards to lift loads. Lacking the free-lift feature found in more complex masts, this type requires greater overhead clearance due to its full extension during lifting. Often used in outdoor environments with ample space, single-stage forklift masts are suitable for applications that don’t demand extensive vertical reach.

- Sections: 1

- Free lift: no

- Ability to extend: no

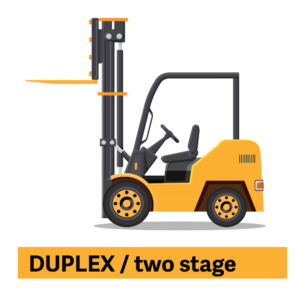

DUPLEX / Two stage

The duplex mast, or two-stage mast, offers increased lifting height and improved visibility. Comprising an inner and outer section, this mast design allows for initial lifting without extending the entire mast, a feature known as free lift. The central hydraulic cylinder effectively raises loads, making it suitable for indoor applications with height restrictions. Enhanced visibility compared to three-stage masts is another advantage of this design.

- Sections: 2

- Free lift: yes

- Ability to extend: yes

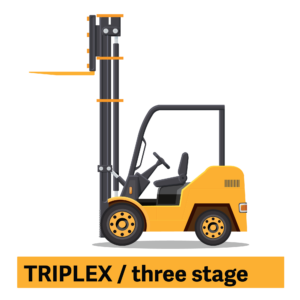

TRIPLEX / Three stage

The triplex mast, or three-stage mast, is the most common and versatile design in forklift masts. Featuring an outer fixed stage and two sliding inner stages, it offers a combination of lifting height and stability. The inclusion of free lift functionality enhances its efficiency in various applications, particularly in warehouses where reaching multiple rack levels is essential.

- Sections: 3

- Free lift: yes (same as duplex)

- Ability to extend: yes, greater than duplex

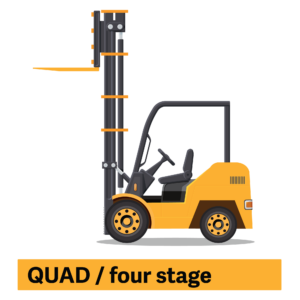

QUAD / Four stage

The forklift quad mast, or four-stage mast, is the pinnacle of forklift mast technology, offering exceptional reach. Comprising four moving sections, this complex design enables unprecedented lifting heights. However, the added complexity of the forklift quad mast can impact visibility and requires specialized operator training to ensure safe and efficient operation.

- Sections: 4

- Free lift: yes (same as triplex)

- Ability to extend: yes, greater than triplex

What to consider when choosing a forklift mast

Lift height: Depending on the desired height, you can choose between simplex, duplex, triplex or quad masts.

Lift Capacity: Consider the weight you need to lift. Taller masts generally have lower lifting capacities.

Height Restrictions: For stacking or operating in confined spaces, a free-lift mast is essential.

Visibility: A free-view mast is ideal when unobstructed frontal visibility is required.

Machine Specifications: Ensure compatibility by considering the brand, type, and serial number of your machine, as not all masts fit every model.

Conclusion

Safe and efficient operation of a forklift starts with choosing the right machine for your material handling needs. Knowing what, how and where you need to lift your loads will help you understand the forklift mast that best suits your task. Have the experts at rentmas guide you through selecting the right forklift for your project.

Frequently asked questions

Do I need a license to operate a forklift?

Yes. Forklift certifications are usually country-specific, meaning that each country has its own unique training requirements, safety standards and regulations. That means your certification may not be recognized in other countries other than where you did your training. You should always check to make sure your certification is up to date and valid in the place where you will be operating a forklift.

What is the difference between a mono and a simplex forklift mast?

A mono mast features a single central column positioned in the middle of the truck, while a simplex mast uses a two-column parallel lift frame design. The simplex mast’s dual-column construction allows it to handle heavier payloads compared to the mono mast, making it more common in standard forklifts where higher load capacities are needed.

How do I decide the right forklift mast height for my project?

When choosing a forklift rental, measure your maximum lifting height requirement and add 15-30 cm (6-12 in) for clearance. Consider any overhead obstacles, rack heights, and door clearances. The mast height when collapsed (closed height) should also clear any doorways or overhead restrictions in your facility.

What are the differences between single-stage, two-stage, three-stage and four-stage masts?

Each forklift mast type offers different advantages in terms of lifting height, visibility, and cost.

- Single-stage forklift mast (Simplex): One fixed set of rails with limited lift height and no free lift but excellent visibility, making them ideal for basic low-height applications

- Two-stage (Duplex): Features two telescoping rails offering moderate lift heights and good visibility with limited free lift, making them suitable for medium-height warehouse operations

- Three-stage (Triplex): A three-nested rail design providing higher lift heights with full free lift capability, making them versatile for most standard warehousing needs, providing maximum lift height while maintaining a lower collapsed height

- Four-stage (Quad): Forklift quad masts utilize four nested rails to achieve maximum lift heights while maintaining reasonable collapsed height, specifically designed for very high-bay warehouses and specialized applications

What maintenance is required for the mast during a long-term forklift rental?

During a long-term forklift rental, the mast should be regularly checked. Regularly inspect mast chains for proper tension and wear, regularly check hydraulic fluid levels and monitor them for any leaks, keep mast rails clean and properly lubricated, pay attention to any unusual noises or movement and alert the rental company immediately.