Need advice on selecting and renting the best excavator for your project? You’re in the right place. This article is designed to assist you in finding the best-suited excavator, get familiar with its applications, and demystify the digital rental journey for you, showing you how easy and simple it is to rent a machine online.

How do I rent an excavator on a digital platform?

Have you ever rented a car online? Booked a flight or a hotel online? If so, you already know how to rent construction equipment online, too. It’s the same principal – selecting your product, dates and location – just applied to a different product: construction equipment.

You can pull up a list of the construction machines available for hire in your area in a matter of just a few minutes on the rentmas platform. Start your search by choosing the type of excavator you need—opt for mini excavators if your project is small or select wheeled excavators for larger construction tasks. Then simply enter the location and dates you’ll need the machine.

Your search will come back with a list of available machines displayed in order of proximity to your selected location. You can use the search’s filters to choose exact technical specifications you need for your rental. rentmas offers a streamlined solution to renting equipment that caters to any size and scale of project.

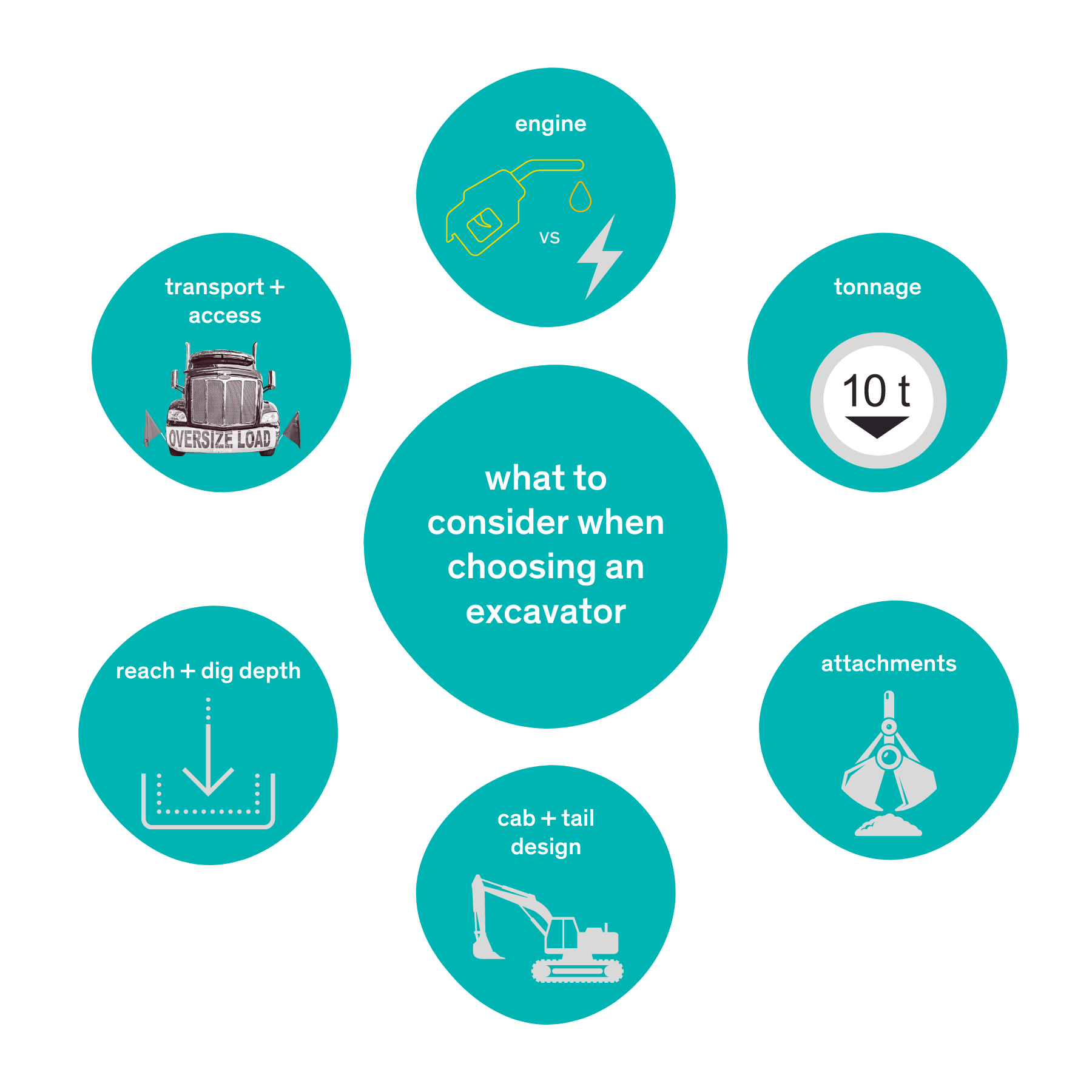

What to consider when choosing an excavator

There are six factors to take into consideration when choosing the right excavator rental:

- Tonnage: When selecting an excavator, a crucial specification to consider is the tonnage. Increased weight of the excavator means increased stability, and this stability allows for an increase in the corresponding digging depth.

- Type of attachments: It’s important to know your task so you can be sure you’re choosing the right attachments for rental. With a wide range of bucket sizes and types, along with attachments like hydraulic hammers and grapples, the attachments you choose set the stage for how well you carry out your work.

- Engine type: The two main types of excavator engines are diesel and electric, and while the majority of excavators you’ll find on the market have diesel engines, there are instances where you’ll need electric. Make sure to inform yourself of the location where you’ll be working – if you’re on a zero-emissions construction site you may be required to rent electric.

- Reach + dig depth: Knowing the maximum dig depth is critical before selecting an excavator, and it’s always best to stay on the safe side and overestimate rather than have too short a boom to reach the depths you need. The reach, on the other hand, will come into play when determining how far your equipment can dig without moving. If accessibility is not a challenge, it’s always better to go for a shorter reach, because longer reaches can slow excavation cycle time.

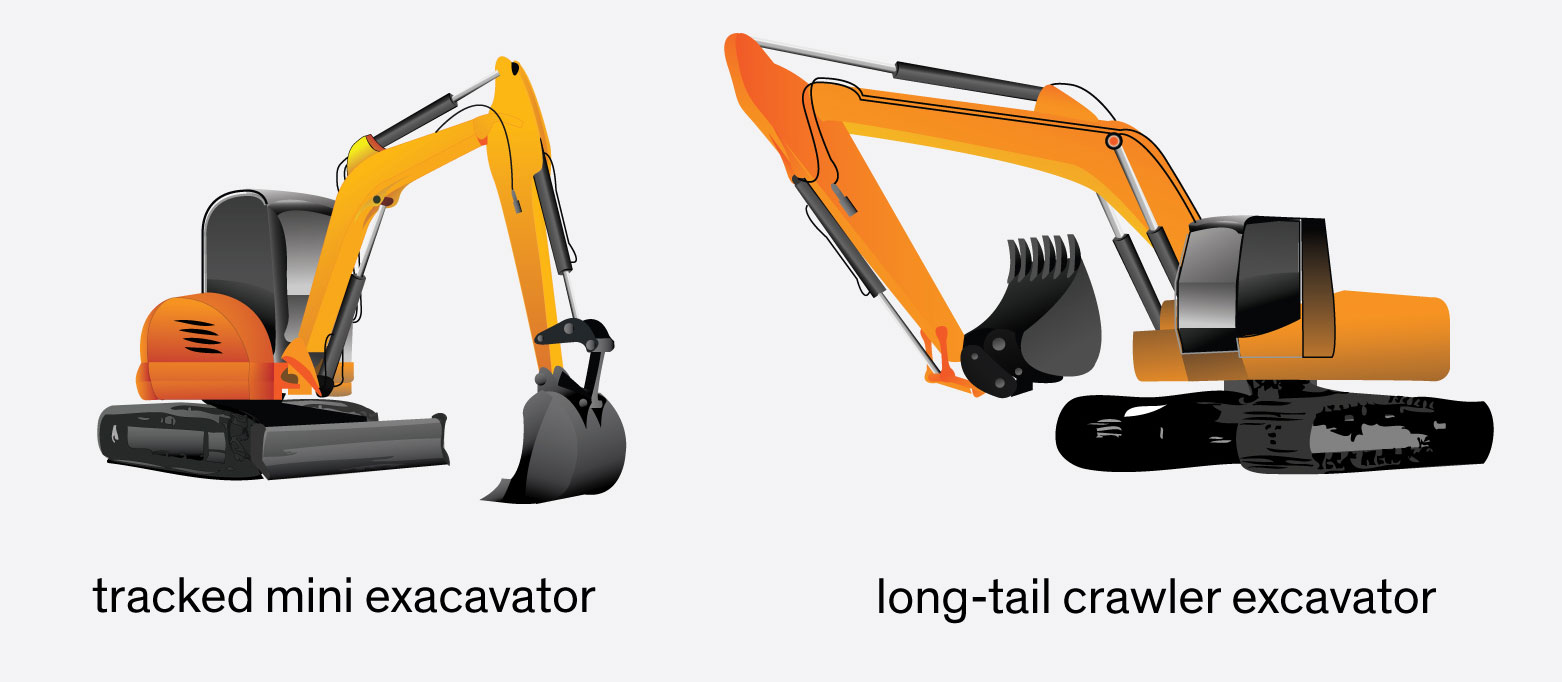

- Tail + cab design: From zero and near-zero tail swing of mini excavators up to large tail swing in larger excavators, the tail of these machines affects stability, mobility, safety, and accessibility. Make sure the tail swing on the excavator you’re looking to rent matches up with your project’s needs. Conversely, the cab on your machine has a big effect on operator working environment and safety. Canopy cabs are open structures found on mini excavators, and feature a simple roof. These cabs should only be used when stability is optimal with no risk of toppling. Most other excavators come with a ROPS (roll-over protective structure) cab, which protect the operator in case of rollover and are often closed and air-conditioned.

- Transport + access: While opting for the most powerful excavator can be appealing, it’s essential to consider how the machine will be transported to the job site and its maneuverability within the area. Choose an excavator that meets your geographic and logistical needs and can be transported effectively to the worksite.

What is the right excavator for my project?

Selecting the right machine for your excavation projects – from small excavators to large excavators to tracked excavators, or perhaps a wheeled excavator – can greatly improve the productivity and efficiency of your project. Making sure you have the right excavator attachments to go with the machine is equally as important. rentmas offers an extensive range of excavators and attachments tailored to your project’s needs. Here’s some inspiration:

- Best for smaller-scale work and spaces: Mini excavators. These compact machines are ideal for operation in smaller-scale and tighter-spaced work environments and benefit indoor projects or sites with restricted access.

- Best for heavy-duty tasks: Crawler excavators. With their robust tracks, sheer weight and hydraulic power mechanisms, these machines excel in lifting heavy debris and soil, ideal for heavy-duty construction jobs and mining operations.

- Best for urban development projects: Wheeled excavators. With the unique design of their wheels, these machines are faster and more maneuverable on concrete and other flat surfaces.

Whatever your project, rentmas has the perfect machine tailored to execute the work as quickly and efficiently as possible.

The mini excavator (up to 6T) – The compact powerhouse

For compact construction sites or limited-access spaces, mini excavators stand as the preferred equipment choice thanks to their unmatched versatility. These nimble machines boast both enhanced maneuverability and superior fuel efficiency, traits that are especially advantageous for interior work or projects where minimal space is available for machine work. Despite their strengths, they can struggle with larger-scale digging operations and might offer reduced operator comfort owing to constraints such as diminished reach capacity, shallower excavation capabilities, more confined operator stations, and potentially complex operating mechanisms.

- Examples of application: Mini excavators are versatile, handling tasks from minor demolitions and material management to stump extraction, digging holes for pool installations, and sewer repairs with precision and efficiency.

- Ideal areas of application: Their compact size makes them perfect for jobs in confined spaces like residential construction, landscaping, and tight urban environments where larger machines can’t operate.

- Unique attributes: Mini excavators offer a range of interchangeable bucket attachments and retractable tracks, enhancing their ability to maneuver in restricted spaces and perform various tasks with precision.

- Not suitable for: These machines have limitations, such as the risk of hydraulic system or track damage if used beyond weight capacity, and they may tip over if overloaded or used improperly, making them unsuitable for deep excavation or handling large materials beyond their lifting capabilities.

The crawler excavator (above 6T) – The heavy-duty champion

In the realm of heavy-duty construction and mining endeavors, crawler excavators (also known as caterpillars or CAT excavators) along with dragline excavators stand out as the unparalleled workhorses. Renowned for making up the largest excavator class that is characterized by sturdy tracks coupled with potent hydraulic power systems, these machines excel in hoisting sizable loads of debris and earth. As pillars of industrial-grade construction, they boast formidable strength and high efficiency.

Nevertheless, due to their sizeable dimensions and sluggish movement speed, these types of hydraulic excavators are not perfectly suited for tasks that necessitate regular movement either across a construction site or between various locations.

- Examples of Application: wheeled excavators are indispensable in their performance in mining, trench digging, landscape grading, site preparation, structure demolition, and heavy lifting.

- Ideal Areas of Application: Excelling in construction, and quarrying, caterpillar excavators are adept at leveling uneven terrain and working on sloped surfaces thanks to their chain wheel system.

- Unique Attributes: These machines feature a specialized boom for versatile motion, a robust undercarriage for load distribution, adjustable tracks for wear compensation, and tensioning devices for track maintenance.

- Not Suitable For: Due to their weight and track design, caterpillar excavators are not recommended for use on hard surfaces like concrete roads, and can damage delicate grounds such as lawns. Their size and speed also limit their effectiveness in projects requiring frequent relocation.

The wheeled excavator – The versatile mover

Wheeled excavators, also known as mobile excavators, are known for their ability to be quickly relocated and for their adaptability. They serve as the construction industry’s flexible powerhouses. Equipped with a range of excavator attachments such as augers, breakers, and grapples, these small yet robust pieces of heavy equipment can perform numerous functions apart from excavation alone. Nevertheless, due to regular movement between sites, they may undergo increased wear and tear.

- Some typical applications: Employed for excavation of urban areas and road construction, mobile excavators excel with their wheeled configuration, offering speed and maneuverability on hard surfaces and the option for outriggers to transition to rough terrain.

- Ideal areas of use: Ideal for tasks requiring frequent job site transitions, wheeled excavators are a mainstay in construction and material handling, thanks to their wheels, speed, and the ability to be equipped with various attachments for different functions.

- What’s unique: Known for their hydraulic prowess, mobile excavators (also known as compact excavators) are recognized for their small size and the ability to navigate tight spaces, with interchangeable buckets and retractable tracks for added versatility.

- Not suitable for: It’s crucial to be aware of performance limitations, such as the risk of tipping when turning with an unbalanced counterweight or when crossing inclines at certain angles, and the potential for damage when digging aggressively or inappropriately.

How do I choose the right excavator for my project?

To choose the right excavator for your project, you’ll need to consider various criteria such as:

- the machine’s ability to lift

- the machine’s stability during operation

- overall operating weights

- distribution of machine weight around its center of gravity

- placement of lifting points

- hydraulic system capabilities

These elements are critical in ensuring that tipping stability is not compromised and hydraulic limits are respected.

When choosing an excavator, it’s important to take into account the force needed both to dig through and transport materials. This may mean equipping the excavator with specific attachments designed for more challenging materials. Buckets are the classic primary attachment and are essential for excavation activities. If choosing to use a bucket attachment, make sure it matches up with both the material being handled and load capacity requirements.

Important considerations and safety requirements

Handling heavy machinery such as excavators requires proper training and understanding. It is essential for operators to be trained in the safe and effective operation of these pieces of equipment and their attachments, including mastery of their functions, compliance with safety standards, and the capability to address any potential malfunctions or complications that may come up during use.

Find a rental company you trust and always get reliable rental equipment

Renting your construction equipment from a trusted rental company that makes sure the rental equipment is properly taken care of is a must. Regular maintenance is incredibly important for ensuring that the equipment continue to operate at their best. This not only maintains the condition of these machines, but also reduces the likelihood of accidents stemming from faulty machinery. rentmas holds its Partners (the rental machine suppliers) to the highest standard, making sure they are as attentive as possible when it comes to machine care and maintenance.

Know your working conditions

It’s important to consider the working conditions appropriate for various types of excavators. For example, crawler excavators should avoid operation on rigid surfaces like concrete roads or well-manicured lawns where they could cause damage.

Frequently asked questions

Why rent an excavator instead of buying one?

Renting an excavator offers cost-effectiveness, flexibility in equipment selection, maintenance and repair convenience, elimination of storage concerns, access to newer models, and avoidance of depreciation, making it a practical choice for short-term projects, occasional use, or businesses that don’t require constant access to heavy machinery.

What are some advantages of renting an excavator?

Renting an excavator provides several advantages, including cost-effectiveness by avoiding the significant upfront investment required for purchasing, flexibility in equipment selection tailored to specific project needs, convenience in maintenance and repair as responsibility typically falls on the rental company, elimination of storage requirements, access to newer models from rental fleets, and avoidance of depreciation concerns, making it particularly advantageous for short-term projects, occasional use, or businesses with varying equipment needs.

What are the various applications of excavators?

Excavators have diverse applications across industries, including construction, mining, agriculture, and forestry. In construction, they are used for tasks such as digging foundations, trenching, and site preparation. In mining, excavators are essential for extracting ore and minerals from the earth. Additionally, they play vital roles in agriculture for tasks like land clearing, irrigation ditching, and drainage work, while in forestry, they are utilized for clearing land and handling timber.

What is the difference between a mini excavator and a crawler excavator?

Mini excavators, which typically weigh less than 6 tons, are the smaller cousins of crawler excavators. They excel in tight spaces with their compact size and maneuverability, making them perfect for landscaping or light demolition. Crawler excavators, on the other hand, occupy all weight classes above 6 tons and as a result pack a bigger punch. Their size translates to greater power for heavy-duty tasks like deep trenching or large-scale excavation projects. While both utilize tracks for movement, crawler excavators trade some maneuverability for the increased stability and digging capabilities crucial for tough jobs.